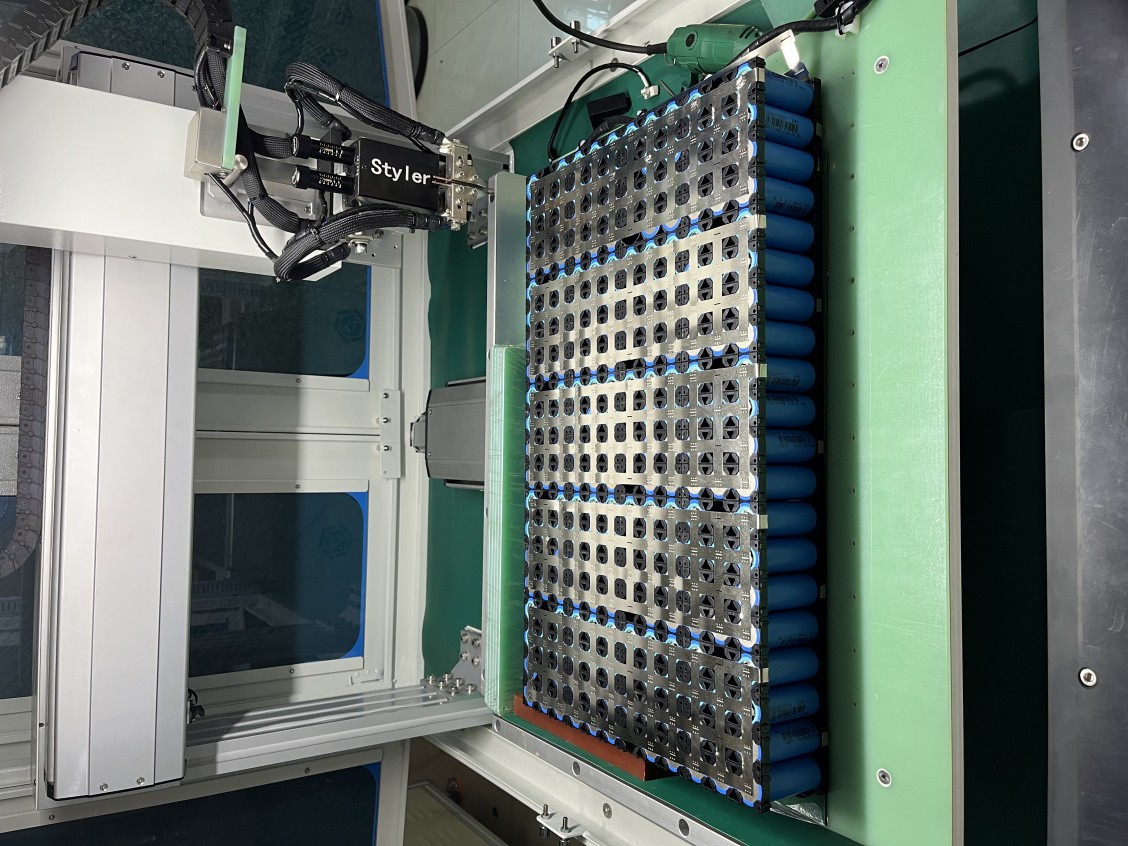

Nyob rau hauv lub ntiaj teb hloov zuj zus sai ntawm kev tsim roj teeb—powering txhua yam ntawm EVs rau cov neeg siv khoom siv hluav taws xob thiab daim phiaj cia—vuam sawv ua ib qho tseem ceeb, tab sis feem ntau nyuaj, txheej txheem rau lub roj teeb pob los ua ke. Kev ncaj ncees ntawm txhua qhov kev sib txuas ncaj qha cuam tshuam rau pob khoom kev nyab xeeb, kev ua tau zoo, thiab kev ua haujlwm ntev. Ntawm STYLER, peb tshwj xeeb hauv kev vuam thiab kev sib dhos ua ke rau kev sib koom ua ke ntawm pob, suav nrog precision ResistanceCov Chaw Welders, high-speed Laser Welding Machine, thiab turnkey Battery Module & Pack Assembly Lines.

We've tau sau kaum nqe lus nug ntau zaus peb pab pawg engineering ntsib txog cov roj teeb pob welding, muab cov kws tshaj lij kev nkag siab los pab koj taug qab nws qhov nyuaj.

1. Dab tsi yog txoj kev vuam zoo tshaj plaws rau kev sib txuas cylindrical cell modules lossis roj teeb pob busbars?

Rau kev sib txuas ntawm cov hlwb rau hauv cov qauv lossis koom nrog cov busbars hauv ib pob, Resistance Spot Welding feem ntau yog ib qho kev xaiv. Nws'sa ceev, nqi-zoo, thiab txhim khu kev qha txoj kev tsim ntau yam kev sib txuas hluav taws xob muaj zog. STYLER cov chaw welders, siv cov thev naus laus zis thev naus laus zis thev naus laus zis, xa qhov tshwj xeeb nrawm thiab ruaj khov, nrog kev tawm tswv yim tam sim no thiab kev tswj hwm kom tswj tau nyias, rhiab cov ntaub ntawv zoo li npib tsib xee-plated busbar.

2. Peb yuav ua li cas tiv thaiv overheating thiab thermal puas rau cov roj teeb hlwb thaum lub sij hawm ntim vuam?

Thermal tswj thaum lub sij hawm ntim khoom yog qhov tseem ceeb. Tus yuam sij yog tswj lub zog tawm tswv yim nrog qhov tseeb ntawm cov ntsiab lus sib txuas. Peb Transistor-based Resistance Spot Welders ua tiav qhov no los ntawm ultra-luv, lub sijhawm ua tiav vuam cycles (milliseconds), txo qis kev sib kis. Rau laser vuam, xaiv qhov tsis raug thiab siv high-speed galvanometer scanners localizes tshav kub input. Peb lub tshuab tuaj yeem ua ke nrog kev saib xyuas thermal kom ntseeg tau tias cov cell nyob ze nyob hauv qhov txwv tsis pub muaj kev nyab xeeb.

3. Aluminium thiab tooj liab-aluminium composites muaj nyob rau hauv pob busbars. Cov kev daws teeb meem vuam yog dab tsi?

Vuam cov ntaub ntawv no yuav tsum tau ua tib zoo xaiv cov txheej txheem. Rau qhov chaw vuam, cov npib tsib xee siab conductivity xav tau tam sim no hauv lub sijhawm luv luv. STYLER's transistor welders xa qhov tsim nyog sai, ruaj khov zog mem tes. Rau laser welding ntawm aluminium busbars thiab kev sib txuas, nws zoo heev. Txawm li cas los xij, rau cov busbars tooj liab nkaus xwb nyob rau hauv pob los ua ke, laser welding muaj teeb meem vim muaj kev xav tau siab thiab thermal conductivity. Ib qho tswv yim thiab pom zoo lwm txoj hauv kev yog siv tooj liab-aluminium composite busbars (cov ntaub ntawv clad), qhov twg cov laser vuam ua rau ntawm txhuas txheej, ua kom muaj kev sib koom ua ke ruaj khov thiab ruaj khov dua.

4. Qhov tseem ceeb npaum li cas yog qhov tseem ceeb ntawm kev huv thiab kev npaj rau pob vuam?

Tseem ceeb heev. Oxides, roj, thiab cov kab mob ntawm cov busbars los yog terminals ua rau tsis zoo weld zoo, muaj zog tiv thaiv, thiab muaj peev xwm ua tsis tau. Cov txheej txheem ntim khoom muaj zog yuav tsum suav nrog kev tu kom zoo (xws li laser tu, plasma tu) tam sim ntawd ua ntej vuam. STYLER's Battery Pack Assembly Lines tuaj yeem koom ua ke cov chaw tu lub tshuab kom huv si kom ntseeg tau tias qhov chaw zoo sib xws rau txhua qhov kev sib txuas.

5. Peb yuav ua li cas thiaj li ua tau zoo nyob rau hauv cov khoom ntim ntim ntau lawm?

Kev sib xws yog los ntawm kev ruaj khov ntawm cov khoom siv, kev saib xyuas cov txheej txheem, thiab kev ua haujlwm tsis siv neeg. Peb cov tshuab muaj cov yam ntxwv:

Real-time Txheej Txheem Saib Xyuas: Ntsuas qhov ua haujlwm tsis zoo (qhov chaw vuam) rau txhua qhov vuam.

Kaw-Loop Adaptive Control: Tsis siv neeg kho qhov ntsuas raws li kev tawm tswv yim.

100% Kev Tshuaj Xyuas Tom Qab Weld: Kev sib koom ua ke ntawm lub zeem muag rau kev tso qhov vuam thiab kev ntsuas hluav taws xob rau hauv cov kab sib dhos kom muaj kev ruaj ntseg zoo.

6. Cov txiaj ntsig tseem ceeb ntawm kev vuam laser hauv kev sib dhos roj teeb yog dab tsi?

Laser Welding muaj qhov tshwj xeeb ntawm kev hloov pauv hauv weld geometry (kab, voj voog, contours), kev ntxhov siab me me, thiab muaj peev xwm los vuam hauv qhov chaw kaw hauv ib pob qauv. Nws yog qhov zoo tagnrho rau vuam module kawg daim hlau, npog seams (qhov twg siv tau), thiab cov duab busbar nyuaj. Nws txo cov cuab yeej hnav thiab ua kom muaj kev kub ceev, zoo nkauj huv seams.

7. Thaum twg yog lub turnkey Battery Pack Assembly Line tsim nyog vs. standalone welders?

Standalone welders yog zoo meej rau R & D, pilot kab, los yog cov txheej txheem sub-assembly. Lub turnkey Battery Pack Assembly Line yog qhov tseem ceeb rau kev sib xyaw ua ke, ntim ntau lawm ntawm cov khoom tiav lossis cov pob khoom. STYLER tsim cov kab uas automate tag nrho cov kab ke: module stacking, busbar tso, vuam (qhov chaw los yog laser), hluav taws xob kuaj, thiab zaum kawg kev koom ua ke. Qhov no maximizes throughput, minimizes tib neeg yuam kev, kom traceability, thiab optimizes pem teb chaw.

8. Koj yuav ua li cas hais txog kev sib tsoo hauv cov roj teeb, uas tuaj yeem ua rau luv luv?

Spatter hauv ib pob yog ib qho kev nyab xeeb loj heev. Nyob rau hauv qhov chaw vuam, nws yog tswj los ntawm optimizing lub weld mem tes puab thiab electrode quab yuam. Peb cov Transistor-based Spot Welders muab kev tswj cov mem tes zoo tshaj plaws, txo qis kev sib tsoo. Nyob rau hauv laser vuam, spatter yog minimized los ntawm kev siv cov roj shielding kom raug, pom zoo focal txoj hauj lwm, thiab tailored tsis. STYLER cov kab ke tau teeb tsa los tsim kom huv si, tawg-tsawg welds tseem ceeb rau pob kev nyab xeeb.

9. Dab tsi peb yuav tsum tau siv los ntsuas qhov zoo ntawm cov khoom hauv ib pob?

Tshaj li kev tshuaj xyuas qhov muag, cov ntsuas kev ntsuas qhov tseem ceeb suav nrog:

Hluav taws xob Resistance/Conductivity: Ntsuas hla txhua qhov sib txuas; Tsawg thiab tsis sib xws kuj tseem ceeb heev rau kev ua haujlwm pob.

Pull/Peel Strength: Mechanical destructive tests on samples kom ntseeg tau tias kev sib txuas ncaj ncees raws li cov lus qhia tshwj xeeb.

Nugget Size / Seam Penetration: Txheeb xyuas los ntawm kev txheeb xyuas hla ntu thaum lub sijhawm tsim nyog.

Txheej Txheem Cov Ntaub Ntawv Teev Tseg: Txhua qhov kev sib txuas tsis sib xws (tam sim no, lub sijhawm, lub zog) raug kaw los ntawm STYLER cov cuab yeej rau kev ua tiav tag nrho.

10. Yuav ua li cas kev lag luam hloov vuam rau cov pob khoom tshiab zoo li CTC (Cell-to-Chassis) lossis cov pob khoom loj?

Cov qauv tsim no thov cov txheej txheem vuam uas tsim kom muaj zog, txhim khu kev qha hluav taws xob thiab qee zaum kev sib txuas ntawm cov txheej txheem loj dua. Lawv thawb cov kev xav tau rau weld qhov tob, ceev, thiab sib xws. High-Power Laser Welders tau siv ntau dua rau cov seam welds ntev ntawm cov khoom ntim khoom thiab cov qauv busbars. STYLER yog nyob rau hauv pem hauv ntej, tsim cov kev daws teeb meem nrog lub zog tsim nyog, kev ua tau zoo, thiab kev nrawm kom ua tau raws li cov kev sib tw tom ntej ntawm cov pob khoom sib dhos.

Xaus

Lub roj teeb pob welding yog ib qho kev qhuab qhia meej tsom rau kev tsim cov khoom siv hluav taws xob zoo tshaj plaws nyob rau hauv ib qho kev ruaj ntseg thiab txhim khu kev qha. Kev sib koom tes zoo thiab kev xaiv thev naus laus zis yog txiav txim siab rau koj cov khoom lag luam ua tiav.

Ntawm STYLER, peb muab cov kev daws teeb meem rau kev sib xyaw roj teeb. Los ntawm kev ruaj ntseg siab ceev ntawm peb Transistor-raws li Resistance Spot Welders thiab hloov tau precision ntawm peb Laser Vuam Systems mus rau tag nrho automation ntawm peb cov roj teeb pob los ua ke kab, peb tau cog lus los txhawb koj kev tsim khoom nrog kev ntseeg siab, innovation, thiab zoo heev.

Npaj los ua kom zoo dua koj cov roj teeb pob vuam txheej txheem? Hu rau pab pawg kws tshaj lij STYLER hnub no rau kev sab laj.

Lub sij hawm xa tuaj: Dec-11-2025